Manufacturing

Tool Room

GALCO Group has the most up to the minute tool room skilful of Producing premium and complex dies our tool shop is supported by An intercontinental quality billet casting facility with the helping Hand of our abundant dies, we can recommend more than 5500 Product outlines to our clients and thus can meet their demands.

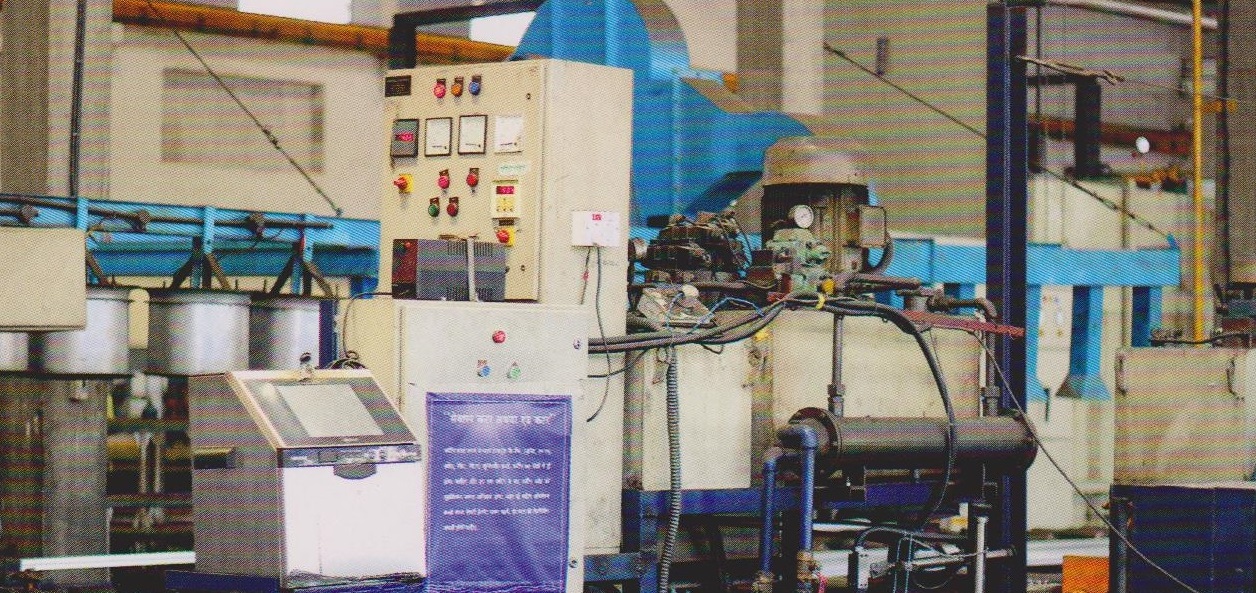

State-of-the-art Manufacturing facilities

The modern plant is equipped with an automatic controlled press, compact hydraulic extrusion press with flexibility to extrude 6”, 7”, 8” and 9” diameter billets. All presses have close controls on the speed and a high degree of stability.

Die components

The main components for Die Toolsets are:

Die Block - This is the main part that all the other parts are attached to.

Punch Plate - This part holds and supports the different punches in place.

Blank Punch - This part along with the Blank Die produces the blanked part.

Pierce Punch - This part along with the Pierce Die removes parts from the blanked finished part.

Stripper Plate - This is used to hold the material down on the Blank/ Pierce Die and strip the material off the punches.

Pilot - This is used to keep the material being worked on in position.

Guide / Back gage / Finger stop - These parts are all used to make sure that the material being worked on always goes in the same position, within the die, as the last one.

Setting (Stop) Block - This part is used to control the depth that the punch goes into the die.

Blanking Dies - See Blanking Punch

Pierce Die - See Pierce Punch.

Shank - used to hold in the presses. it should be align and situated at the center of gravity of the plate.

Die Forming

Progressive die with scrap strip and stampingsForming dies are typically made by tool and die makers and put into production after mounting into a press. The die is a metal block that is used for forming materials like sheet metal and plastic. For the vacuum forming of plastic sheet only a single form is used, typically to form transparent plastic containers (called blister packs) for merchandise. Vacuum forming is considered a simple molding thermoforming process but uses the same principles as die forming. For the forming of sheet metal, such as automobile body parts, two parts may be used, one, called the punch, performs the stretching, bending, and/or blanking operation, while another part, called the die block, securely clamps the workpiece and provides similar, stretching, bending, and/or blanking operation. The workpiece may pass through several stages using different tools or operations to obtain the final form. In the case of an automotive component there will usually be a shearing operation after the main forming is done and then additional crimping or rolling operations to ensure that all sharp edges are hidden and to add rigidity to the panel.

The belt system used for handling the aluminium extrusions keeps the soft metal scratch-free and shiny! The billets for extrusion are cast in-house in a DC Caster, in the right chemical composition, filtering the molten metal through ceramic filters to achieve a high degree of cleanliness and grain refinement for best end-use results.

Plant & Machinery

Gal co Group has in-house powder coating line with following production capacity and film Thickness:

Horizontal Powder Coating line with an annual capacity of 2400MT

Minimum Film Thickness = 60 Microns

Available Powder Types-

A) Epoxy Powder B) Epoxy Polyester Powder C) Polyester TGIC Powder

We follow all the procedure as per the norms of qualicoat guarantee period : 5 to 10 Years.Apart from a large quality of exported products, without help we provide 10% of the total Domestic production on our country through our large facility and widespread set of Promotional links.